Product Code: PP230C

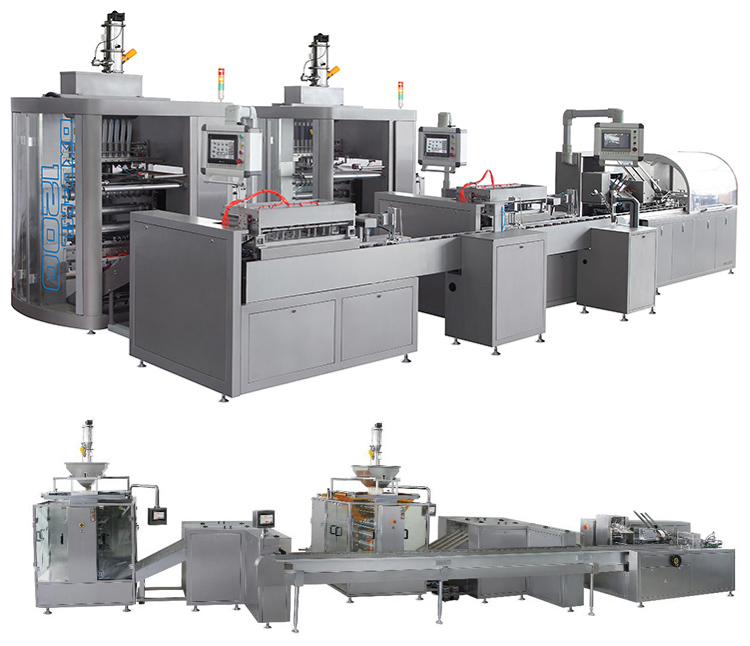

This machine is applicable for dosing granule and sealing in form of 4 side sealed sachet, include the sachet forming, product dosing, filling and sachet sealing processes, with single cutting or string sachet cutting.

This machine is applicable for dosing granule and sealing in form of 4 side sealed sachet, include the sachet forming, product dosing, filling and sachet sealing processes, with single cutting or string sachet cutting. the detail application description as following table:

| Issue | Application Description |

| Applicable Sealing Style | 4 sides sealing |

| Applicable Products | Configure with volumetric cup, capable to pack granule products. (e.g. desiccantdriers, seasonings, Cajun seasoning, instant coffee, sea salt, sugar, brown sugar, chicken essence, salt, instant oat, wildfire spice, popping candy, pop rocks, oatmeal, etc.) |

| Applicable PackagingMaterial | Laminate Heat sealable packing materials such as OPP/PE, BOPP/VMPET/PE, PET/AL/PE etc. |

Typical applications:

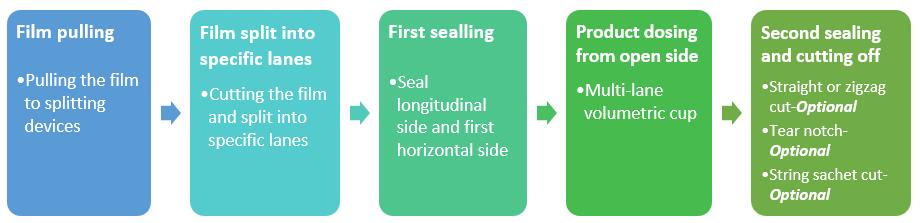

The working processes include: The machine pull laminate packaging film to the film splitting devices, and the film split into specific lanes, then go through the sealing mold to seal longitudinal side and first horizontal side, in the meanwhile, the dosing device dose the product into the sachet through the open side, then will do the last side sealing and cutting off. Upon the different product.

Standard Features

• Multi-lane volumetric cup filler for granule dosing

• PLC & HMI Touch Screen Control

• Intelligent PID temperature controller

• 3 heating section design with temperature balance adjustment system

• Servo motorized sub-processes

• Automatic sachet length adjustment

• Film edge trimming and collecting

• Embossing type coder integrated

• Out-feed conveyor

• Powered film unwinding with film tension control

• Automatic film centering control

• Stainless steel 316 construction for product touching parts and 304 for other main parts

Optional Features

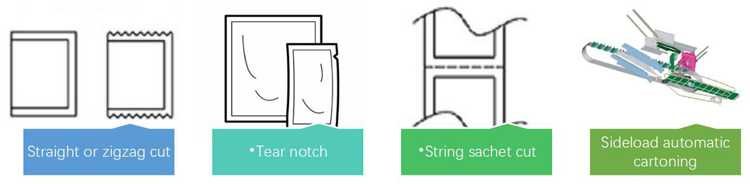

• Straight or zigzag cut

• Tear notch

• Inkjet, or thermal transfer printer

• String sachet cut

• Empty sachet detection and rejection

• Static elimination

• In-feed system

• Sideload automatic cartoning solutions

| Catalogue/3Z-xxx-E | 500 | 900 | 1200 |

| Sachet Size-Length(mm) | 50-120 | 50-120 | 50-120 |

| Sachet Size-Width(mm) | 32-105 | 32-105 | 32-105 |

| Lanes | Customize | Customize | Customize |

| Film Width(mm) | 500 | 900 | 1200 |

| Packing Speed(CPM) | 30-60 | 30-60 | 30-60 |

| Power Requirement | AC380 3P/50HZ | AC380 3P/50HZ | AC380 3P/50HZ |

| Power Consumption(kW) | 10 | 12 | 15 |

| Max Outer Diameter of Film Roll (mm) | 300 | 300 | 300 |

| Inner Diameter of Film Roll (mm) | 75 | 75 | 75 |

Following is the link of video playlist on our Youtube site

Automatic Multi-Lanes 4-Side Sealed Sachet Form Fill Seal Machine

If need more information , please contact us at: cs@gloex.com.cn