Product Code : PP296B

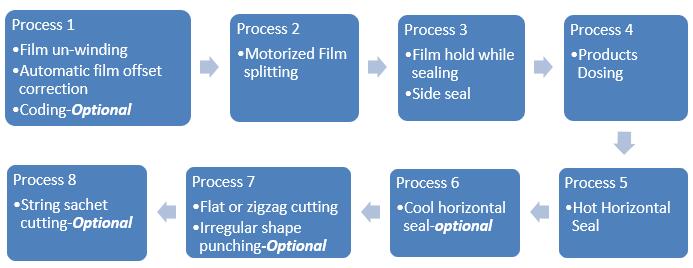

This machine is applicable for dosing liquid, semi-liquid products and sealing in form of sachet, with 3 side sealed style, include the sachet forming, product dosing, filling and sachet sealing processes, In different patterns of sealing, and flat, zigzag cutting or other irregular shape punching.

By configure with different accessories, suitable for food, cosmetic, medicine packing such as ketchup, chocolate, mayonnaise, olive oil, chili sauce, honey, drinks, jelly, medicine, shampoo, cream, lotion etc.

This machine is applicable for dosing liquid, semi-liquid products and sealing in form of sachet, with 3 side sealed style, include the sachet forming, product dosing, filling and sachet sealing processes, In different patterns of sealing, and flat, zigzag cutting or other irregular shape punching.

By configure with different accessories, suitable for food, cosmetic, medicine packing such as ketchup, chocolate, mayonnaise, olive oil, chili sauce, honey, drinks, jelly, medicine, shampoo, cream, lotion etc.

Standard Features

1) Mainly stainless-steel 304 construction

2) Stainless-steel 304 for product touching parts

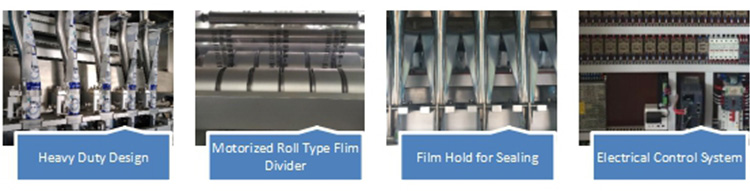

3) Heavy duty design suits for high speed operation

4) No waste of film design, no reserved film edge required

5) Motorized roller type film dividing device6) PLC & Touch screen HMI control

7) Guided servo motorized film pulling device integrated with horizontal seal

8) Pneumatic piston pumps dosing for each lane with manual dosing range adjustment

9) Intelligent PID temperature controller

10) Door open and machine stop interlock

11) No packaging film and machine stop interlock

Optional Features

1) Stainless Steel 316 for product touching parts

2) Sealing pattern

3) Flat or Zigzag cutting off

4) Round and other irregular shape cutting off

5) String sachets

6) Tear notch

7) Embossing, ribbon, inkjet or laser coding

8) Cool horizontal seal

9) Dual products dosing with double layer tube

10) Servo motorized pumps

11) CIP connectable and/or double jacket heat insulation hopper

12) Grouping conveyor with/without sachet weight checking, rejecting and target weight calibration

13) Sachet counting system14) Cartoning or bagging system

| Type 4W-xxx | 280YS | 480YS | 880YS |

| Dosing Method | Volumetric cup | Volumetric cup | Volumetric cup |

| Packaging Speed | 35-60 sticks/min/lane | 35-60 sticks /min/lane | 35-60 sticks /min/lane |

| Max film width | 280 mm | 480 mm | 880 mm |

| Sachet Size-Length | 20-110 mm | 20-110 mm | 20-110 mm |

| Sachet Size-Width | <=120 mm | <=120 mm | <=120 mm |

| Lanes | Customized | Customized | Customized |

| Filling Accuracy | +/- 1-2% | +/- 1-2% | +/- 1-2% |

| Filling Range | 1-100 g | 1-100 g | 1-100 g |

| App Air Supply | 0.3 CBM/min, 0.6 Mpa | 0.4 CBM/min, 0.6 Mpa | 0.6 CBM/min, 0.6 Mpa |

| Power Consumption | 2.7 kw | 3.3 kw | 3.6 kw |

| Power Supply | 380 V /3 Phases/ 50 Hz | 380 V /3 Phases/ 50 Hz | 380 V /3 Phases/ 50 Hz |

Note:

1) The speed of packaging subject to the filling volume, size of sachet, characteristic of liquid and accuracy requirement

2) The filling accuracy subject to the packaging speed, filling volume and characteristic of liquid

| No | Components | Material / Brand | Origin |

| 1 | Products Touching Parts | Stainless Steel 304 | |

| 3 | Frame and structure | Mainly Stainless Steel 304 | |

| 4 | Programmable Logic Controller | Mitsubishi/Siemens | Japan/Germany |

| 5 | Touch Screen | Weinview/Delta | Taiwan, China |

| 6 | Servo Motor | Tamagawa | Japan |

| 7 | Frequency Convertor | Convo-Bosch | Germany |

| 8 | Key Electric Components | Schneider/Siemens | Germany |

| 9 | Cylinder, Filter | Airtac | Taiwan |

| 10 | Temperature Controller | Omron | Japan |