Product Code: PP109

It is apply for heat sealable pre-made pouch packing and sealing. Such as flat pouch, stand up pouch, with or without zipper. The detail application description as following table:

| Issue | Application Description |

| Applicable Sachets | Suitable for heat sealable pre-made pouch filling and sealing. Such as flat pouch, stand up pouch, with or without zipper. |

| Applicable Products | Configure with different dosing devices, capable to pack with liquid, powder, granule, or other irregular solidity materials |

| Applicable PackagingMaterial | Pouches are made of Heat sealable packing materials such as OPP/PE, BOPP/OPP/PE, PET/AL/PE |

It is apply for heat sealable pre-made pouch packing and sealing. Such as flat pouch, stand up pouch, with or without zipper. The detail application description as following table:

| Issue | Application Description |

| Applicable Sachets | Suitable for heat sealable pre-made pouch filling and sealing. Such as flat pouch, stand up pouch, with or without zipper. |

| Applicable Products | Configure with different dosing devices, capable to pack with liquid, powder, granule, or other irregular solidity materials |

| Applicable PackagingMaterial | Pouches are made of Heat sealable packing materials such as OPP/PE, BOPP/OPP/PE, PET/AL/PE |

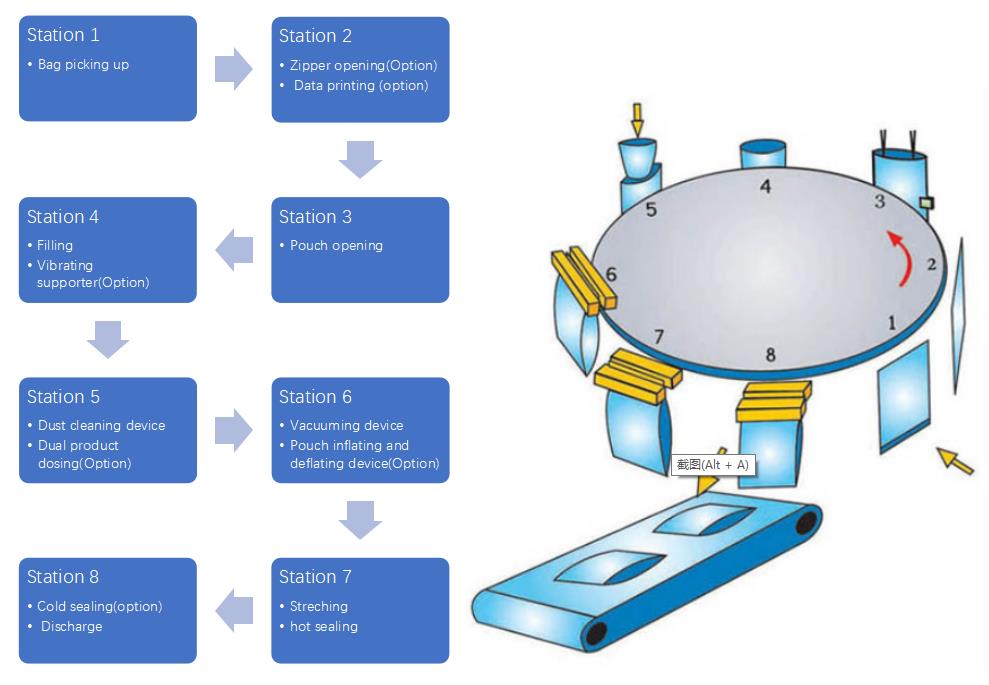

8-station design to meet complex packaging process requirements

Configured with different dosing devices, capable to pack liquids, powder, granule, or other irregular solidity materials8

PLC touch screen control, easy to operation, easy for troubleshooting

PID temperature control system for reliable sealing effect

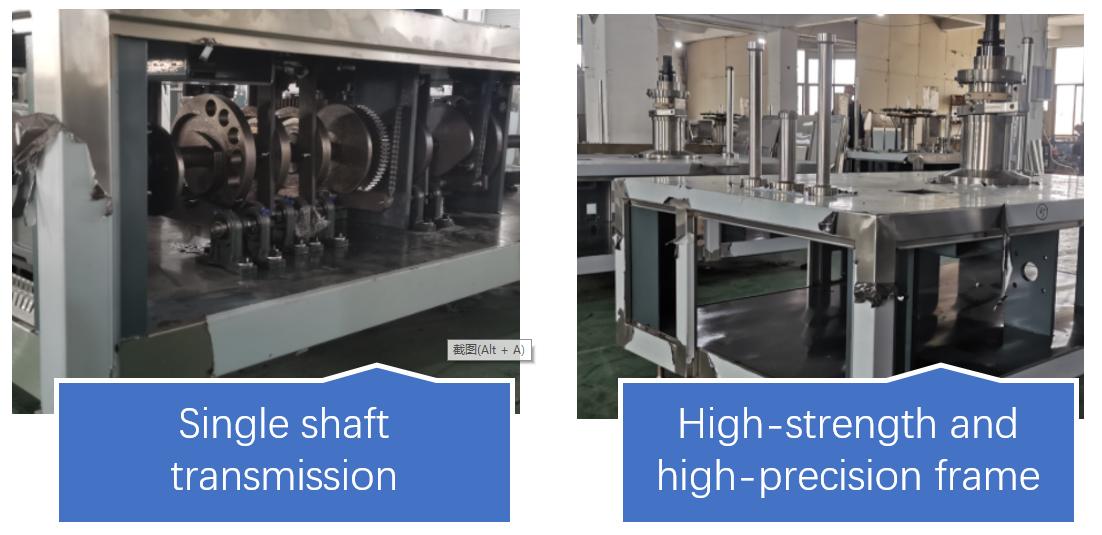

Single shaft transmission, accurate operation, high reliability, easy maintenance

Multi-mechanical transmission station, accurate stroke, reliable operation

High-strength and high-precision frame, higher precision, high-strength cam, more stable operation

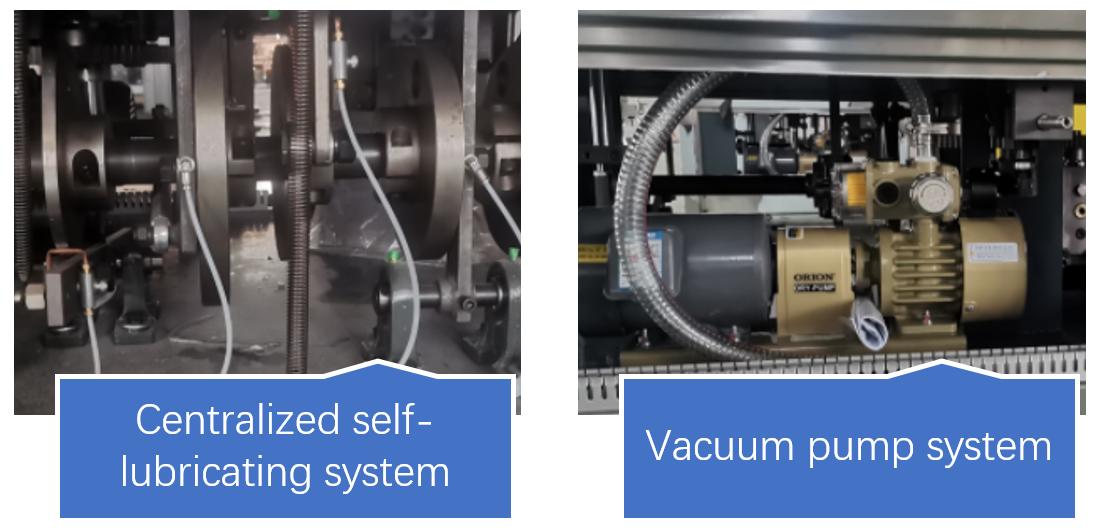

Configured with vacuum pump system for pick up and open bag, reduce the air consumption of the whole system, energy saving and noise reduction

Synchronous bag width adjustment device, 1 rotating wheel adjustment controls all stations to fit with new bag width.

Centralized self-lubricating system, with small lubricating oil tanks and distribution pipes, easy maintenance

No bag opening, no filling and sealing

No filling, no sealing

In order for adapting different requirements, the customized products can be supplied with the optional features as following

| No | Feature | Description | |

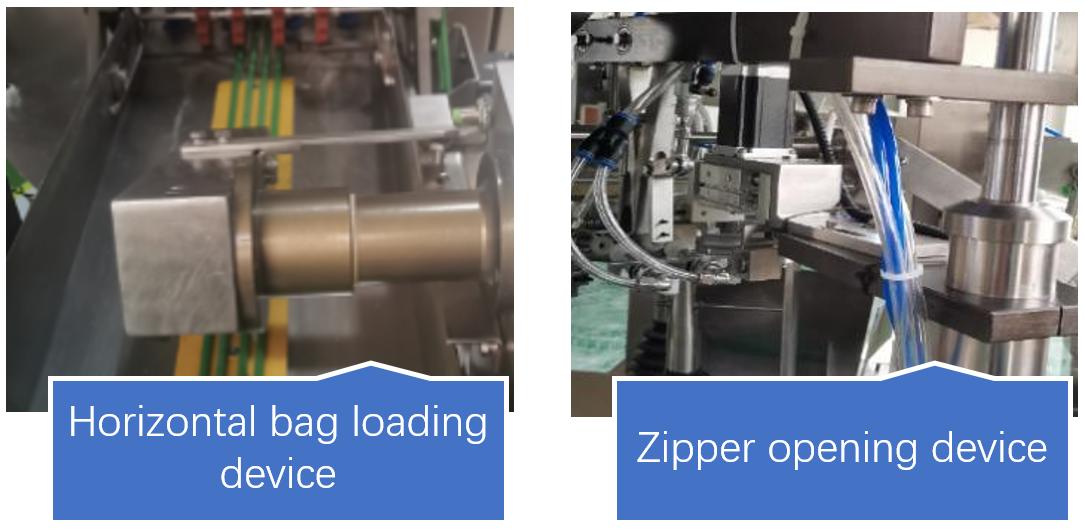

| 1 | Zipper opening device | 1) The clamps are arranged in front and back position to apply for small bag width, minimum to 100 mm 2) Mechanical driven zipper opening device moves up and down, high reliability | |

| 2 | Horizontal Pouch Loading Device | 1) increase bags quantity in the bag magazine2) 2)zipper bag loading more reliable | |

| 3 | Date printing device | 1) Ribbon Coding Device 2) Inkjet printer 3) Laser Printer | |

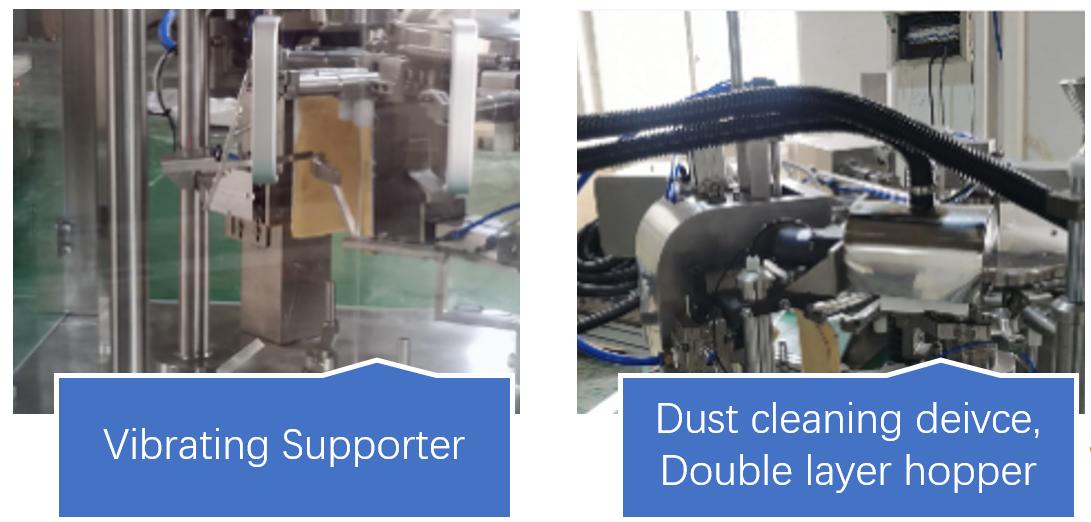

| 4 | For Dusty products | Configured with: 1) Double layer hopper to collect the dust 2) Dust Remover on the Seal Area | |

| 5 | For loose materials | Configured with 1) Product Vibrating Supporter 2) Product Settler | |

| 6 | Vacuuming Device | Vacuuming after filling but before sealing | |

| 7 | Pouch Inflating and Deflating Device | Apply for deflating and inflating before sealing | |

| 8 | Equipped with vacuum turntable, | Independent vacuum chambers, fast and reliable | |

| 9 | Computerized temperature control system | Self fault alarming, emergency stop | |

| 10 | Computerized vacuum control system | Self fault alarming, emergency stop | |

| 11 | No bag alarm (and stop) | ||

| Type/1K-xxxxx | 8-200 | 8-250 | 8-300 |

| Process Stations | 8 | 8 | 8 |

| Pouch Size-Length(mm) | 100-350 | 100-350 | 100-350 |

| Pouch Size-Width(mm) | 70-200 | 110-250 | 180-300 |

| Packing Speed (pouches/min) | 20-60 | 20-60 | 20-60 |

| Power Requirement(V/Hz) | 380VAC 3P+N+E 50HZ | 380VAC 3P+N+E 50HZ | 380VAC 3P+N+E 50HZ |

| Power Supply(kW) | 3.0 | 3.0 | 4.0 |

| Compress Air Required(Mpa) | 0.6-0.8 | 0.6-0.8 | 0.6-0.8 |

| Compress Air Consumption(m3/min) | 0.3 | 0.3 | 0.3 |

| Approximate Weight(kg) | 1500 | 1500 | 1800 |

| Dimension(mm) | 2160*1600*1500 | 2160*1600*1500 | 2420*1820*1500 |