Product Code: PP146

This machine is applicable for subject to configure with different dosing device , filling with power, granule or liquid into premade pouch and sealing

This machine is applicable for subject to configure with different dosing device , filling with power, granule or liquid into premade pouch and sealing , the detail application description as following table :

| Issue | Application Description |

| Applicable Pouch | Pre-made stand up pouch, flat pouch, 4 sides sealed pouch, spout pouch, other irregular shaped flat or stand up pouches, with/without zipper etc. |

| Applicable Products | Configure with different dosing devices, capable to pack with liquid, powder or granule etc. |

| Applicable Packaging Material | Laminate Heat sealable packing materials such as OPP/PE, BOPP/OPP/PE, PET/AL /CPP etc. |

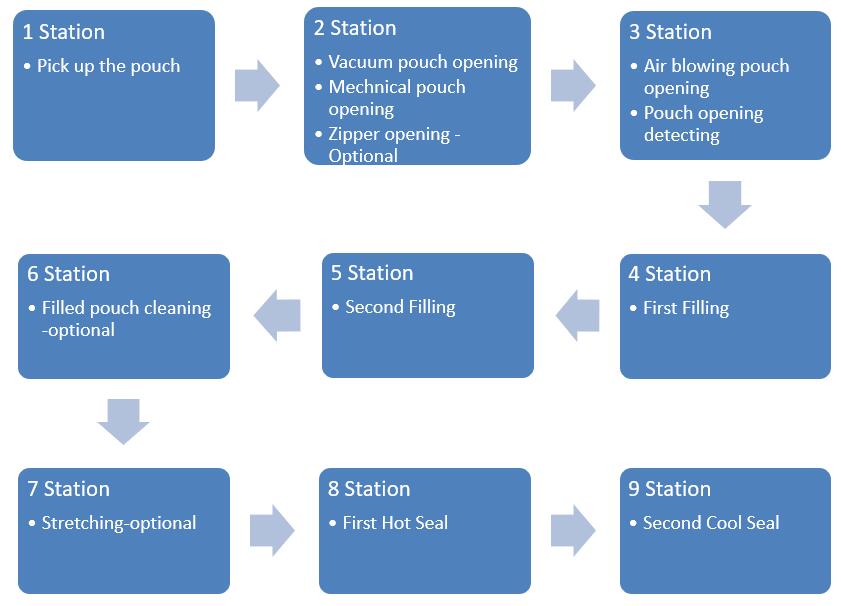

Following are the typical working process diagram:

Note: above is the typical process flow , subject to the optimization result from the pouch type, size or products

Standard Features

1)Apply for premade flat or stand up pouch fill and seal as the standard, with zipper as the option

2)Rigid carbon steel structure, Stainless steel 304 for surface and product touching parts

3)Anodic oxidation and/or harden aluminum for main movement beam and pouch holding bars

4)PLC and touch screen control

5)Intelligent PID temperature controller

6)Frequency converting motor driven and 3 separate divider indexing sub-systems to enable stable and high-speed movement

7)Up to 9 stations enable complete and flexible processes design, like twice filling or sealing

8)Mechanical detecting of no pouch/not completely open, and no fill no seal interlock

9)Mechanical pouch picking up design, ensure accurate positioning

10)Vacuum system powered by vacuum pump

11)Mechanical pouch stretching before sealing, get more better sealing aspect

12)Configure with different dosing device for different type of products

Optional Features

Horizontal type pouch magazine

Zipper opening

Ribbon or other type of coding

Multiple fills or seals

Water chiller for seals

| Type 1G-xxxx | 4P-210-1 | 4P-210-2 |

| Packaging Speed | 30-60 pouches/min | 60-100 pouches/min |

| Lanes | 1 Pouch/cycle | 2 Pouches/cycle |

| Vertical Sealing Station | 1 | 2 |

| Pouch Size-Length | 100-320mm | 100-320mm |

| Pouch Size-Width | 90-210 mm | 50-100 mm |

| Film Pulling Driven | Servo Motor | Servo Motor |

| Power Consumption | 4.0 kw | 5.0 kw |

| Power Requirement | AC 380V 50/60HZ | AC 380V 50/60HZ |

| Applicable pouch | Premade flat or stand up pouch | Premade flat or stand up pouch |

| Type 1G-xxxx | 4P-250-1 | 4P-250-2 |

| Packaging Speed | 30-60 pouches/min | 60-100 pouches/min |

| Lanes | 1 Pouches/cycle | 2 Pouches/cycle |

| Vertical Sealing Station | 1 | 2 |

| Pouch Size-Length | 100-350mm | 100-320mm |

| Pouch Size-Width | 110-250 mm | 60-120 mm |

| Film Pulling Driven | Servo Motor | Servo Motor |

| Power Consumption | 4.5 kw | 5.5 kw |

| Power Requirement | AC 380V 50/60HZ | AC 380V 50/60HZ |

| Applicable pouch | Premade flat or stand up pouch | Premade flat or stand up pouch |

Following is the related video link on our YouTube site.

Horizontal Type Premade Pouch Packaging Machine

If need more support, please contact us at: cs@gloex.com.cn