Product Code: PP113

This machine is applicable for powder or small granule dosing and filling in form of can, jar or bottle, the detail application description as following table:

| Issue | Application Description |

| Applicable Products | Suitable for filling powdered materials, such as milk powder, protein powder, coffee powder, glucose powder, health care products and spices. |

| Applicable Containers | Suitable for bottles, round containers, mental cans with spec. #300, #307, #401, #502 |

This machine is applicable for powder or small granule dosing and filling in form of can, jar or bottle, the detail application description as following table:

| Issue | Application Description |

| Applicable Products | Suitable for filling powdered materials, such as milk powder, protein powder, coffee powder, glucose powder, health care products and spices. |

| Applicable Containers | Suitable for bottles, round containers, mental cans with spec. #300, #307, #401, #502 |

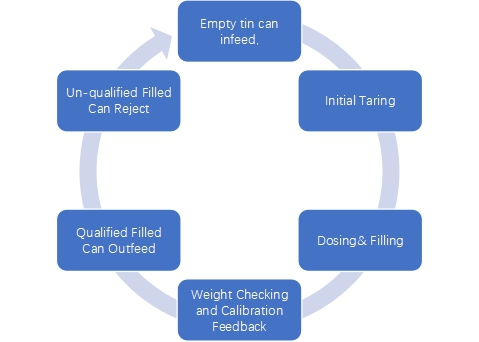

Rotary working model to finish from empty infeeding to filling to qualified cans outfeed/ unqualified cans rejection by turning table.

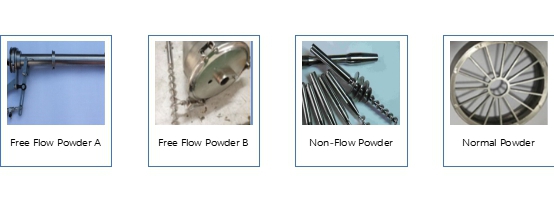

By configuring with different design screw augers, such as standard auger, forcing model auger, capable to fill different products with typical features.

For some particular features, such as dusty, or free-flow, vacuum dusty collection device or shutoff valve will be configured to ensure the filing and packing performance.

Standard Features

Suitable for powder or small granule dosing and filling in form of can, jar or bottle

PLC &Touch screen HMI control enable easy operation parameter setting up and troubleshooting

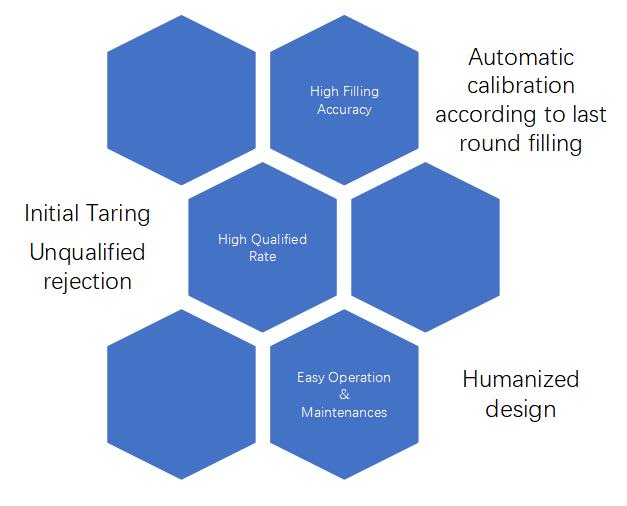

Configured weight checking sensor ensure the weights no effected when the density changing

Weight checking/self-calibration and eliminating unqualified products

Configured vibrating device on filling station to fill smoothly and anti-bridge arch

Turntable able to accurately position the container automatically, no bottles no filling.

Easy to change over different cans, easy to clean after packing

Optional Features

1) Powder loading device, auger loading/ powder vacuum loading

2) Double filling stations

3) Horizontal feeding auger to ensure the powder density remains same when working with powder vacuum loader.

4) Vacuum dust collection system

5) Empty cans infeeding, finished packed cans collection table

6) Date printing device

| Catalogue/1R-xxxxx | ||

| Auger Set | 1 | 1 |

| Container Diameter (mm) | 50-180 | 30-100 |

| Container Height (mm) | 50-350 | 50-150 |

| Packing Speed (cans/min) | 20-50 | 20-40 |

| Hopper Volume (L) | 50 | 26 |

| Filling Accuracy | 1-3% | 1-3% |

| Power Requirement | 380VAC 3P+N+E 50Hz | 380VAC 3P+N+E 50Hz |

| Power Consumption(kW) | 2 | 2 |

| Compress Air Required (Mpa) | 0.6 | 0.6 |

| Compress Air Consumption(m3/min) | 0.2 | 0.2 |

In order to form a production line, the corresponding filling, sealing machines are necessary accessories.