Product Code: PP111

This machine is applicable for powder or small granule dosing and filling in form of can, jar or bottle, the detail application description as

following table:

This machine is applicable for powder or small granule dosing and filling in form of can, jar or bottle, the detail application description as

following table:

| Issue | Application Description |

| Applicable Products | Suitable for filling powdered materials, such as milk powder, protein powder, coffee powder, glucose powder, health care products and spices. |

| Applicable Containers | Suitable for bottles, round containers, mental cans with spec. #300, #307, #401, #502 |

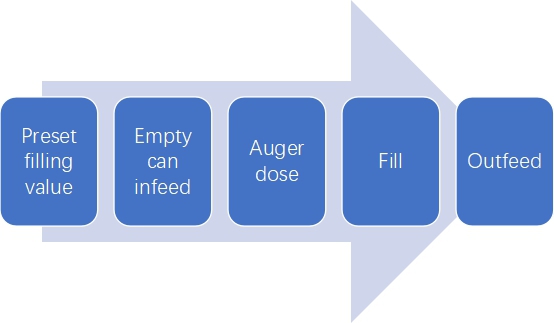

Inline model to finish working process from empty can infeed to fill to outfeed.

It’s the basic high cost-effective model for powder filling packing

By configuring with different design screw augers, such as standard auger, forcing model auger, capable to fill different products with typical features.

For some particular features, such as dusty, or free-flow, we will configure vacuum dusty collection device or shutoff valve to ensure the filing performance.

Standard Features

Suitable for powder or small granule dosing and filling in form of can, jar or bottle

PLC &Touch screen HMI control enable easy operation parameter setting up and troubleshooting

Servo motors driving, more accurate dosing, faster speed

Transparent hopper, operation visible, other product touching parts constructed by stainless steel 304

Dosing hopper equipped with dust filter device, anti-dust design for other filling accessories

Auger accessories quick dissemble and installation design to adapt to different dosing ranges or powder features

Height adjustable devices, to adapt different height of the container

Chain conveyor with cylinder controlling for bottles or jars distributing and positioning

Filling range stepless adjusting

Storing 10 groups of technical parameters for the different products, convenient for product changing

Optional Features

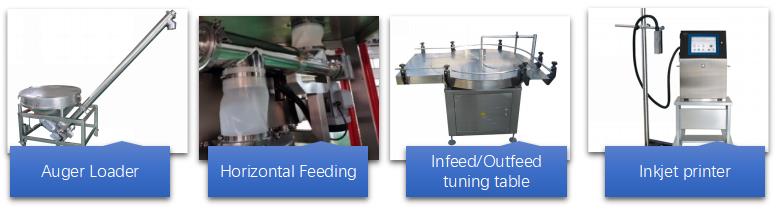

1) Powder loading device, auger loading/ powder vacuum loading

2) Containers lift for filling

3) Horizontal feeding auger to ensure the powder density remains same when working with powder vacuum loader.

4) Vacuum dust collection system

5) Empty cans infeeding, finished packed cans collection table

6) Date printing device

| Catalogue/1R-xxxxx | 2A | 2B |

| Auger Set | 1 | 1 |

| Container Diameter (mm) | 50-100 | 75-127 |

| Container Height (mm) | 100-200 | 100-200 |

| Packing Speed (cans/min) | 20-30 | 20-30 |

| Hopper Volume (L) | 26 | 50 |

| Power Requirement | AC 380V 3P+N+E 50HZ | AC 380V 3P+N+E 50HZ |

| Power Consumption(kW) | 2 | 2 |

| Compress Air Required (Mpa) | 0.6 | 0.6 |

| Compress Air Consumption(m3/min) | 0.2 | 0.2 |

In order to form a production line, the corresponding filling, sealing machines are necessary accessories.