Product Code: PP252

This machine helps the cans, jars move from the pallets and convey these containers into the production line. Mostly it applies to the canned powder line or canned granules line which requests to depalletize from low level position.

This machine helps the cans, jars move from the pallets and convey these containers into the production line. Mostly it applies to the canned powder line or canned granules line which requests to depalletize from low level position.

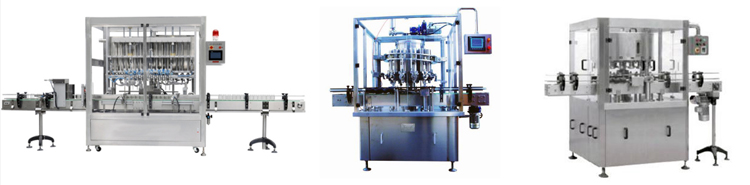

Following are the reference style of packaging

The Layer pads and top frames raise up or go down to suite the height of full pallet and place the containers into the conveyor for the next working flow.

The empty pallets will be removed and stacked manually or automatically as option

Standard Features

1) Apply for empty can depalletizing

2) Include processes of can lifting and falling, pushing and sorting

3) Speed adjustable

4) Stainless steel 304 for frame & cabinet

5) Stainless steel 304 for lifting platform and can pushing device

6) PVC construction for accumulation conveyor belt

7) Configure with servo motorized can lifting system

8) PLC and touch screen control

9) Manual Layer Pad removal

10) Manual empty pallet discharge

Optional Features

1) Automatic Layer Pad removal

2) Automatic empty pallet discharge

| Production Capacity | 2-3 cycles /minute subject to the skill of operator |

| Applicable Can Specification | Diameter 60-150mm Height 80-200mm |

| Maximum Pallet Stack | 1300L*1300W*1500H mm |

| Power Supply | 380 V, 50HZ, 3 Phase, 1.2KW |

| Dimension | 4500*2000*2700mm |

Field Pictures

In order to form a production line, the corresponding filling, sealing machines are necessary accessories.

If need more support, please contact us at: cs@gloex.com.cn