Product Code : PP302

It is applicable for the type of erect pre-glued, flat cartons erecting, opening, product loading from side and finally tucked or sealed with glue.

Configure with range of collating, grouping, loading device and upstream process line, like Vertical Baggers, Horizontal Wrappers etc. to create a completely automated and effective packaging system.

It is applicable for the type of erect pre-glued, flat cartons erecting, opening, product loading from side and finally tucked or sealed with glue.

Configure with range of collating, grouping, loading device and upstream process line, like Vertical Baggers, Horizontal Wrappers etc. to create a completely automated and effective packaging system.

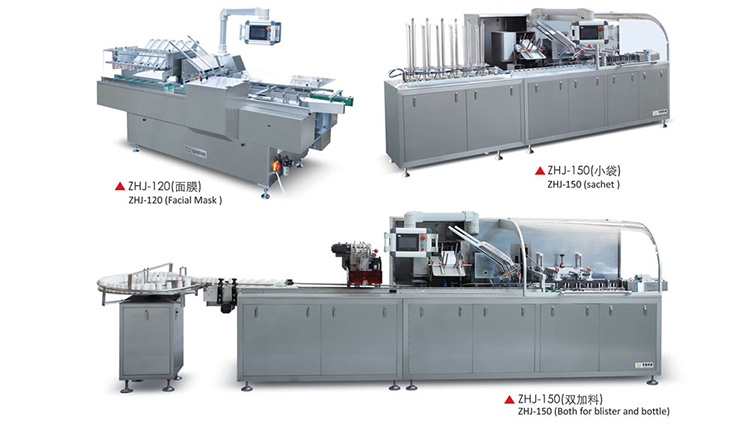

Following are the reference:

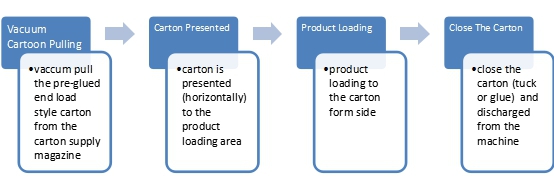

The working processes include: A flat, pre-glued end load style carton is pulled via vacuum from the carton supply magazine. The bottom of the carton is closed (tuck or glue methods available) and the carton is then presented (horizontally) to the product loading area. Following the loading of the product, the machine cycle is initiated and the top of the carton is closed (tuck or glue methods available) and the completed package is discharged from the machine.

Following are the typical working process diagram:

Standard Features

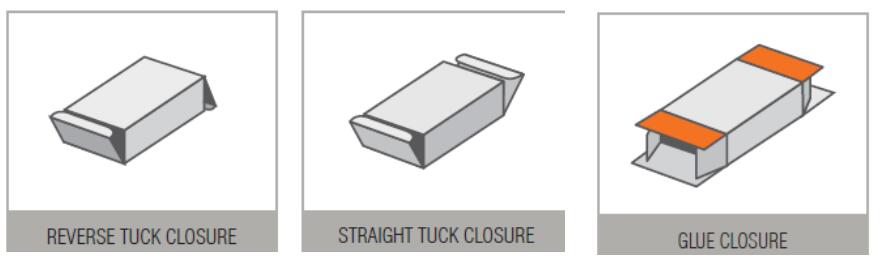

1) Apply for tuck type carton

2) Ergonomics and balcony design to separate the mechanical part on the rear, stainless steel 304 construction for main parts

3) Clutch brake applied with main drive motor, Mechanical overload control

4) Oscillating arm carton pick up and opening enable faster speed, which powered by vacuum pump and cam

5) Various marking system as option

6) Reliable leaflet feeding system, length of folding adjustable

7) Easy faster changeover, regulation only instead of parts replacement

8) PLC and touch screen HMI for operation interface and trouble shooting

9) No carton, machine stops interlock

10) No Leaflet, empty carton rejection and alarm

11) No product, carton and Leaflet interlock and alarm

Optional Features

1) Embossing, Ink-jet or laser marking options

2) Tuck, glue or other special closures

3) Special product infeed system

4) Pre-folded leaflet or leaflet folding from flat sheet/reel

| Type: ZHJ-xxx | 120 | 150 |

| Speed | Up to 120 cartons/minute | Up to 150 cartons/minute |

| Carton Quality | 250-300g/m2 | 250-300g/m2 |

| Carton Size Range(L*W*H) | (50-190)×(25-120)×(12-70)mm | (50-190)×(25-90)×(15-70)mm |

| Leaflet Feeding Unit | Include | Include |

| Unfolded Leaflet Size | (110-260)×(100-180)mm | (110-260)×(100-180)mm |

| Leaflet Folding Range | 1-4 folders | 1-4 folders |

| Leaflet Quality | 55-70g/m2 | 55-70g/m2 |

| Power Supply | 380V50H , 3 Phase , 2KW | 380V50H , 3 Phase , 2KW |

| Compressed Air Supply | 0.5-0.7Mpa, >=0.3m3/min | 0.5-0.7Mpa, >=0.3m3/min |

| Dimension(L*W*H) | 3300×1200×1700mm | 3300×1200×1700mm |

| Weight | 1500kg | 1500kg |

![]()